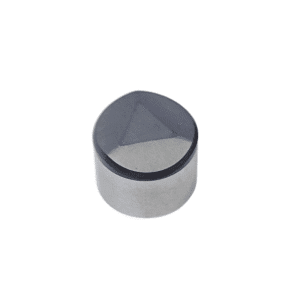

PDC Shaped Cutter

PDC cutter, or PDC button, is a high-efficiency cutting element commonly used in oil and gas, mining, water well drilling, and geological exploration.

Versatility and Specialized

By altering the shape of the diamond table, PDC cutters can be engineered to match specific drilling conditions. For example, arc-shaped cutters offer improved stability, cutting control, and extended service life in interbedded formations, while triangular shaped cutters excel in penetrating hard, compact rock. In short, shaped PDC cutters are designed to enhance performance in targeted formations, providing our clients with versatile options to tackle complex and variable drilling environments.

product advantage

Built for Rough Conditions and High Impact

The exceptional shearing efficiency of PDC cutters comes from their hardness and abrasion resistance. However, this extreme hardness also leads to impact vulnerability — an unavoidable

challenge in most drilling operations.To overcome this, a PDC layer is combined with a tungsten carbide substrate, significantly improving impact resistance. Yet, to further unlock the

full potential of PDC cutters — broadening their application range and reducing costs in both time and resources — continued material and structural improvements are essential.

Diamond layer optimization

The diamond layer makes direct contact with the formation, and its quality largely determines the lifespan of the drill bit. We focus on producing cutters with high impact resistance—without compromising abrasion performance.

Special interface design

The interface between the PCD layer and tungsten carbide substrate is the most critical zone in a PDC cutter. It must balance mechanical strength and thermal resistance, while surviving extreme drilling conditions. WE engineering the interface properly to avoiding delamination and improving cutter life.

Advanced manufacturing

Diamond synthesis requires a complex balance of time, pressure, and temperature. We are an experienced manufacturer of synthetic diamonds, equipped with cubic press machines that give us full control over the production process. This allows us to make swift adjustments to meet our clients’ specific requirements.

Cobalt leaching

Thermal damage is one of the most common issues in PDC cutters. It can result not only from poor thermal management but also from the mismatch in the coefficient of thermal expansion (CTE) between carbon and cobalt. One effective solution is cobalt leaching, which helps relieve internal stress caused by this difference. Varying the depth of cobalt leaching results in different types of cutter products, each optimized for specific applications.

model | shape | diameter (mm) | height | diamond thickness |

|---|---|---|---|---|

1304 | Arc surface | 13.44 | 4.5 | 3.0-3.5 |

1308 | Arc surface | 13.44 | 8 | 3.0-3.5 |

1304 | Ridge | 13.44 | 4.5 | 3.0-3.5 |

1308 | Ridge | 13.44 | 8 | 3.0-3.5 |

13 | Triangular | customize | customize | 3.0-3.5 |

16 | Triangular | customize | customize | 3.0-3.5 |

19 | Triangular | customize | customize | 3.0-3.5 |

*The diameter tolerance is ± 0.03mm.

*The height tolerance is ± 0.1mm.

*The diamond thickness tolerance is ± 0.1mm.

CUSTOMIZATION

We understand that standard products may not always meet the diverse and unpredictable challenges faced in the field. That’s why we’re glad to offer customized solutions tailored to your specific needs.

Get in touch with us— we’ll work with you to develop the ideal solution.