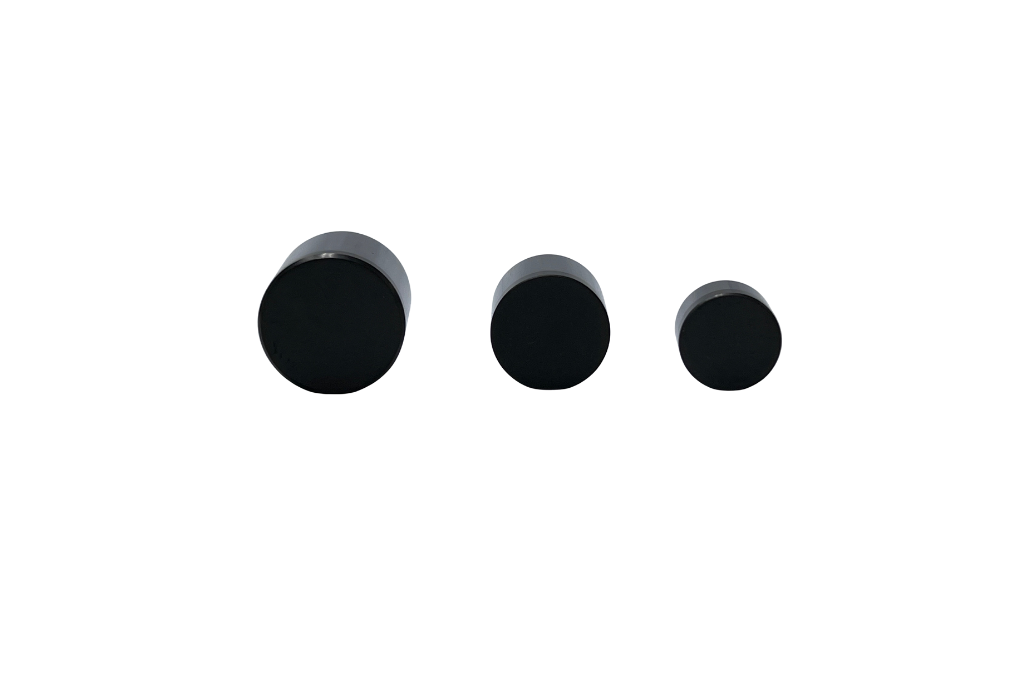

PDC Flat Cutter

Flat PDC cutters provide stable and consistent cutting performance, making them ideal for high penetration drilling in medium to hard formations with aggressiveness.

MORE DETAILSPDC Dome Cutter

Dome cutters operate more durable than flat cutters, especially when drilling through soft to medium formations, enhancing lifespan and impact resistance.

MORE DETAILSPDC Shaped Cutter

With its contoured PDC surface design, shaped PDC is optimized for better cutting performance in complex interbedded formations, offering improved stability and efficiency in challenging drilling conditions.

MORE DETAILS

Durable. Tough. Impact and Wear Resistant.

Nowadays, PDC drill bits are the most commonly used drilling tools in oil, gas, mining, tunneling, and geological exploration.

At the core of the PDC bit is the PDC compact, the primary functional component embedded in the bit. In principle, PDC cutters work by cutting (flat compact) or chiseling (dome compact) into the formation.

Compared to traditional alloy bits, PDC bits offer higher drilling efficiency because most rock formations have lower resistance to cutting than to impact.

Need Some Helps?

We are here to help you find the most suitable solution.