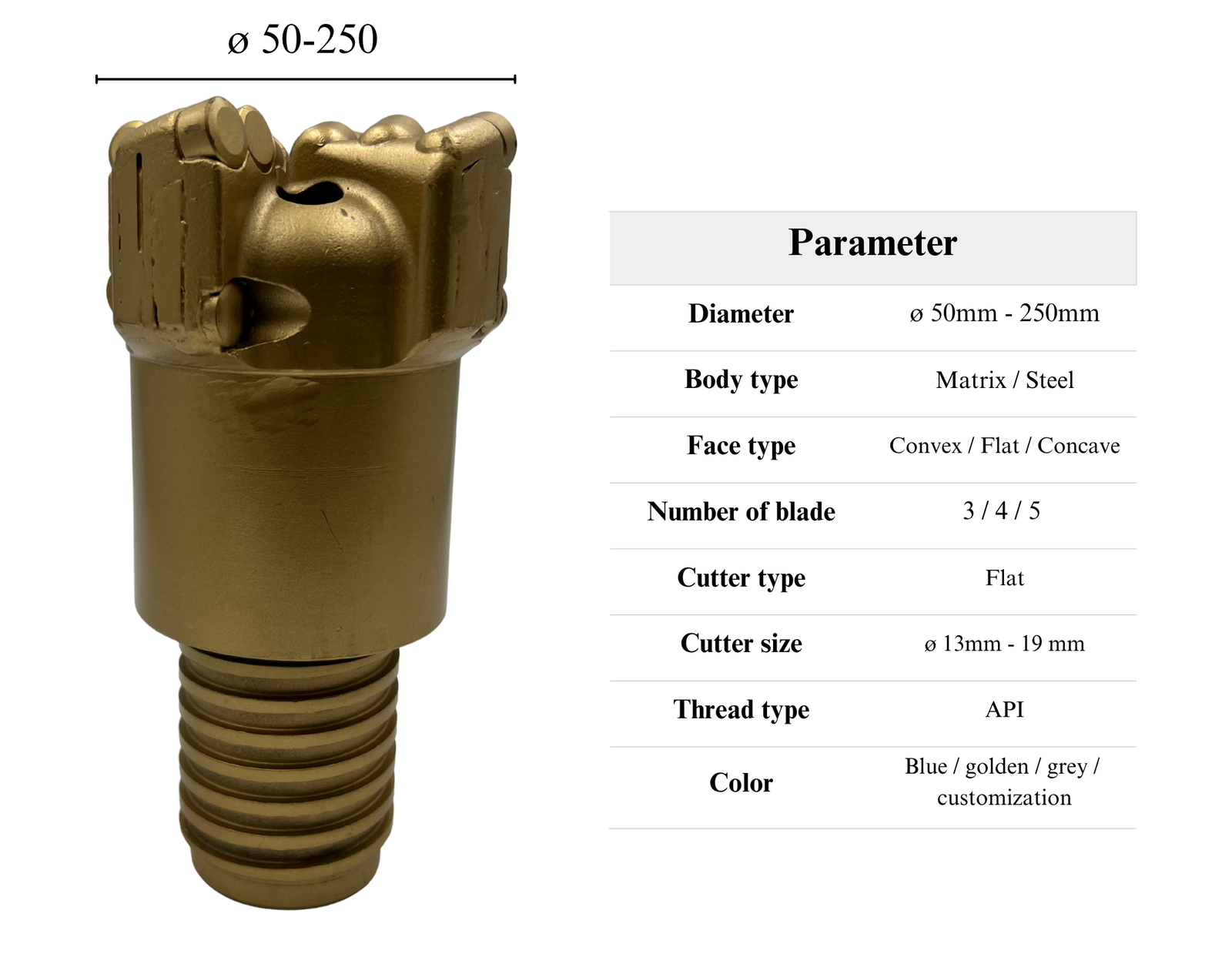

PDC Drill Bit

A PDC drill bit is a type of drilling tool that features polycrystalline diamond compact (PDC) cutters embedded into its body. It typically consists of two main components: the PDC cutters and the bit body that holds them in place.The bit body itself comes in two main types—matrix body and steel body—each offering distinct advantages to suit different drilling environments and application needs.

Engineered Variants for Every Drilling Challenge

The two main components of a PDC drill bit—the bit body and the PDC cutters—offer a wide range of combinations to accommodate the diverse challenges encountered in drilling projects. These combinations can be refined by adjusting several key factors: the number and curvature of blades, cutter specifications, cutter layout, back rake and side rake angles, cutter quantity, chip removal and mud flow design, bit body type (matrix or steel), gauge protection strategies, and more. By carefully considering these parameters alongside actual field conditions, a tailored drill bit solution can be developed to meet specific operational requirements.

product advantage

All about efficiency and stability

To maximize drilling performance and reduce time and resource costs, a sophisticated drill bit design is essential.Using advanced modeling tools such as FEA, CFD, and specialized

design software, we simulate and analyze to identify the optimal theoretical solution.This is further strengthened by our extensive manufacturing experience

and continuous feedback from the field, ensuring both performance and reliability in every drill bit we produce.

Optimized drill design

Generally, our PDC drill bits feature three crown profiles—convex, flat, and concave—each combined with specific spiral angles and gauge structures to enhance contact stability, reduce the bouncing, whirling, ensure torque transfer efficiency, maintain drilling trajectory, and ensure consistent borehole diameter.

Effective PDC layout

The layout of PDC cutters on the blades and bit body is a critical aspect of drill bit design. Based on software simulations and field testing, our bits are engineered with optimized cutter placement tailored to stress and wear distribution. Additional cutters are strategically positioned in highly abrasive zones to enhance durability and cutting efficiency—all aimed at maximizing performance and extending service life.

Smart fluid routing and chip evacuation

Mud and thermal management play a critical role in both the efficiency and lifespan of a PDC drill bit. Thermal failure can severely damage the bit and jeopardize the entire drilling project. Understanding this, we design our drill bits with optimized blade and cutter spacing, appropriate fluid channel geometry, and sufficient junk slot volume to maximize fluid flow and heat dissipation.

Multiple combinations

We offer a wide range of customizable combinations—spanning cutter types, bit body styles, design features, thread connections, and even color options—providing maximum flexibility without compromising on performance.

*The diameter tolerance is ± 0.03mm.

*The height tolerance is ± 0.1mm.

*The diamond thickness tolerance is ± 0.1mm.

CUSTOMIZATION

We understand that standard products may not always meet the diverse and unpredictable challenges faced in the field. That’s why we’re glad to offer customized solutions tailored to your specific needs.

Get in touch with us— we’ll work with you to develop the ideal solution.